商铺名称:大德汇成科技(厦门)有限公司

联系人:蔡子杰(先生)

联系手机:

固定电话:

企业邮箱:2241555929@qq.com

联系地址:厦门市湖里区金钟路11号1301室之二

邮编:

联系我时,请说是在汽配名企网上看到的,谢谢!

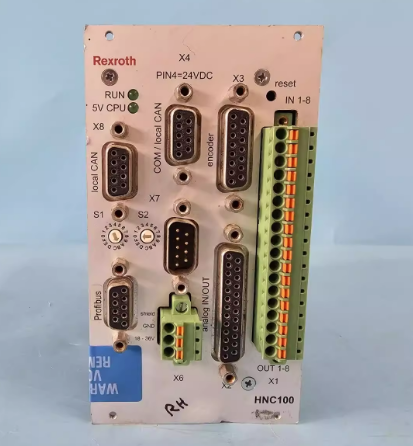

- ?品牌?:REXROTH(博世力士乐)

- ?型号?:VT-HNC100-1-23/W-08-P-0 R900958999

- ?类型?:数字轴控制器

- ?系列?:VT-HNC100系列

-

?高精度控制?:

- 利用最新数字信号处理技术和高分辨率编码器,实现快速响应和超高精度控制。

- 能够快速精准地调节电机的速度和位置。

-

?多轴控制与闭环调节?:

- 可控制多达四个轴,支持液压与电力驱动的闭环控制。

- 能够实时监测和调整系统运行状态,确保高度位置、速度和压力控制。

-

?可编程数控配置?:

- 用户可根据具体需求编程和配置,灵活适配不同工业场景。

- 实现精确的运动控制。

-

?工业级防护设计?:

- 采用IP30防护等级,具备抗振动、抗冲击和耐气候性。

- 适应恶劣工业环境,确保设备长期稳定运行。

-

?多协议支持?:

- 配备PROFIBUS DP总线接口,兼容CANopen、INTERBUS-S等主流现场总线协议。

- 可与其他设备和系统无缝集成。

-

?光纤冗余与自愈?:

- 支持双光口光纤环网冗余功能,故障自愈时间<10ms。

- 保障通信稳定性,适用于对可靠性要求高的场景。

-

?反馈闭环控制?:

- 通过从电机传感器获取反馈信息,实现闭环控制,提高了系统的稳定性和精度。

-

?抗干扰能力强?:

- 能够在噪声干扰等复杂环境中正常工作。

-

?增益切换功能?:

- 可以使伺服电机运行和停止时使用不同的增益,也可以通过外部端子切换增益。

-

?自适应抑振控制?:

- 能够检测到机械共振点后自动设置滤波特性来抑制机械系统的振动。

-

?数控机床?:

- 用于控制各种轴(例如X、Y、Z轴)的运动,以实现工件的精确加工。

-

?自动化生产线?:

- 集成到自动化生产线中,用于控制机械臂、传送带和其他执行器的运动,提高生产效率。

-

?机器人技术?:

- 用于控制工业机器人的关节运动,使机器人能够执行各种任务,如装配、搬运和焊接。

-

?材料处理?:

- 用于控制切割、成型和其他加工设备,确保精确的材料处理。

-

?测试和测量设备?:

- 用于控制测试和测量设备中的运动,确保实验和测试的准确性。

-

?半导体制造?:

- 用于控制半导体制造过程中的各种设备,包括精密的定位和运动。

供应VT-HNC100-1-23/W-08-P-0放大器DCS系统库存原装

供应VT-HNC100-1-23/W-08-P-0放大器DCS系统库存原装

VT-HNC100-1-23W-08-P-0 R900958999伺服控制模块

VT-HNC100-1-23W-08-P-0 R900958999伺服控制模块

VT-HNC100-1-23W-08-P-0 R900958999 数字轴控制器 Rexroth图片

VT-HNC100-1-23W-08-P-0 R900958999 数字轴控制器 Rexroth图片

REXRTOH VT-HNC100-1-23-W-08-P-0-R00958999 数字轴控制器

REXRTOH VT-HNC100-1-23-W-08-P-0-R00958999 数字轴控制器

?VT-HNC100-1-23/W-08-P-0 R900958999 REXROTH 是博世力士乐公司生产的一款高性能数字轴控制器?,以下是对其的详细介绍:

一、基本信息

二、技术特点

三、功能特性

四、应用领域

021-0TP70

120-1TE13-0AA4

134-6GD01-0BA1

2094-BC04-M03-S

288-5CM01-0AAO---?288-5CM01-0AA0

288-IST40-0AA0----288-1ST40-0AA0

6SE7021-0TP70

A5E02822120

A5E36524726

A5E36717797

ATS48C41Q

DSSR122

LDZ10500424.040

P143311A2MC468J

P14331TFAMCZ08L

PP30012HS

SXWAOV8XX10001

SXWASPXXX10001

SXWDOA12X10001

SXWPS24VX10001

SXWTBASW110002

SXWTBIOW110001

SXWTBPSW110001

SXWUI16XX10001

SXWUI8D4X10001

2866776

3AUA0000074145----BGDR-01C

3AXD50000016732

3BHB005922R0001

3BHB006208R0001

3BHB006338R0001

3RK1903-0AK10

6ES7331-7RD00-0AB0

6ES7331-7TF01-0AB0

CI854BK01 3BSE069449R1

CM-KRN

EDK82EV222

HD90S-C1-PS2

HIEE200130R0002

LNC500

MFE180-04AN-046A-4+L518+N8020

WF16AF1M22

114-0AA02-0AA2

225-0BE37-5AA0

323-1BH01-0AA0

3AFE64348221-----NPBA-12

3AFE64605666----APOW-01C

3AUA0000021344

3BHB043813R0001

3RW4037-1BB14

407-0DA01-0AA0

407-0KA02-0AA0

412-2XG04-0AB0

416-2XN05-0AB0

421-1BL00-0AA0

422-1BL00-0AA0

431-1KF00-0AB0

432-1HF00-0AB0

443-1EX11-0XE0

4AT3032-8DD40-0FA0

64378660-----CDP-312R

64646842

6ES5951-7LB21

6ES7312-5BF04-0AB0

6ES7407-0DA01-0AA0

6ES7412-2XG04-0AB0

6ES7416-2XN05-0AB0

6ES7421-1BL00-0AA0

6ES7422-1BL00-0AA0

6ES7432-1HF00-0AB0

6fc5114-0aa02-0aa2

6FX2001-6AA12-1AF7

6SL3210-1PE31-5UL0

A06B-6400-H102

A5E00234283

A5E38977502

ACS530-01-033A-4

APOW-01C

ATV610U55N4

CDP-312R

DFE32B

PMC35.2-000?

PMM13.3-A288

PSR105-600-70

PSTX210-600-70

SDCS-I0B-23

VW3A3607

ZPOW-7B1C

1、 Basic Information

Brand: REXROTH (Bosch Rexroth)

Model: VT-HNC100-1-23/W-08-P-0 R900958999

Type: Digital axis controller

Series: VT-HNC100 Series

2、 Technical features

High precision control:

Utilizing the latest digital signal processing technology and high-resolution encoders to achieve fast response and ultra-high precision control.

Can quickly and accurately adjust the speed and position of the motor.

Multi axis control and closed-loop regulation:

It can control up to four axes and support closed-loop control of hydraulic and electric drives.

Capable of real-time monitoring and adjustment of system operation status, ensuring control of altitude position, speed, and pressure.

Programmable Numerical Control Configuration:

Users can program and configure according to specific needs, flexibly adapting to different industrial scenarios.

Realize precise motion control.

Industrial grade protection design:

Adopting IP30 protection level, it has anti vibration, anti impact and weather resistance.

Adapt to harsh industrial environments and ensure long-term stable operation of equipment.

Multi protocol support:

Equipped with PROFIBUS DP bus interface, compatible with mainstream fieldbus protocols such as CANopen and INTERBUS-S.

Can seamlessly integrate with other devices and systems.

Fiber optic redundancy and self-healing:

Support dual port fiber optic ring network redundancy function, with a fault self-healing time of less than 10ms.

Ensure communication stability, suitable for scenarios with high reliability requirements.

3、 Functional characteristics

Feedback closed-loop control:

By obtaining feedback information from motor sensors, closed-loop control is achieved, which improves the stability and accuracy of the system.

Strong anti-interference ability:

Capable of working normally in complex environments such as noise interference.

Gain switching function:

It is possible to use different gains when the servo motor is running and stopped, and the gain can also be switched through external terminals.

Adaptive vibration suppression control:

Automatically set filtering characteristics to suppress the vibration of the mechanical system after detecting the mechanical resonance point.

4、 Application Fields

Numerical Control Machine Tool:

Used to control the motion of various axes (such as X, Y, Z axes) to achieve precise machining of workpieces.

Automated production line:

Integrated into automated production lines, used to control the movement of robotic arms, conveyors, and other actuators, improving production efficiency.

Robotics technology:

Used to control the joint movements of industrial robots, enabling them to perform various tasks such as assembly, handling, and welding.

Material handling:

Used to control cutting, forming, and other processing equipment to ensure precise material handling.

Testing and measuring equipment:

Used to control the movement in testing and measuring equipment, ensuring the accuracy of experiments and tests.

Semiconductor manufacturing:

Used to control various equipment in the semiconductor manufacturing process, including precise positioning and motion.